Low-viscosity base oils meet industry regulatory criteria as well as occupational safety and environmental protection regulations and technical requirements such as solution behavior, extreme temperature resistance, variable viscosities and outstanding, defined boiling behavior.

Physical Parameter

|

Typical data |

Method |

Pilot |

Pilot |

Pilot |

Pilot |

Pilot |

Pilot |

Pilot |

Pilot |

Pilot |

Pilot 140 |

Pilot 150H |

Pilot 295 SR |

|

|

Low aromatic Grades | Medium Aromatic Grades | |||||||||||

|

Appearance

|

Visual

|

Clear & colorless

|

Clear & colorless

|

Clear & colorless

|

Clear & colorless

|

Clear & colorless

|

Clear & colorless

|

Clear & colorless

|

Clear & colorless

|

Clear & colorless

|

Clear & colorless | Clear & colorless | Clear & colorless |

|

Color (Saybolt)

|

ASTM D 156

|

30

|

30

|

30

|

30

|

30

|

30

|

30

|

30

|

25 | 24 | 24 | |

|

Initial Boiling Point (IBP)

|

ASTM D86

|

220 °C

|

235 °C

|

236 °C

|

250 °C

|

260 °C

|

280 °C

|

280 °C

|

310 °C

|

300 °C

|

260 °C | 260 °C | 256 °C |

|

Final Boiling Point (FBP)

|

ASTM D86

|

243 °C

|

275 °C

|

272 °C

|

295 °C

|

320 °C

|

320 °C

|

360 °C

|

360 °C

|

350 °C

|

330 °C | 320 °C | 296 °C |

|

Density @ 15 °C

|

EN ISO 12185

|

820 kg/m3

|

820 kg/m3

|

820 kg/m3

|

820 kg/m3

|

820 kg/m3

|

820 kg/m3

|

820 kg/m3

|

820 kg/m3

|

860 kg/m3

|

816 kg/m3 | 816 kg/m3 | 818 kg/m3 |

|

Flash Point (PM)

|

EN ISO 2719

|

min. 88 °C

|

min. 100 °C

|

min. 100 °C

|

min. 110 °C

|

min. 110 °C

|

min. 130 °C

|

min. 130 °C

|

min. 140 °C

|

min. 160 °C

|

min. 120 °C | min. 110 °C | min. 118 °C |

|

Kinematic Viscosity @ 40 °C

|

DIN 53015

|

1.9 mm²/s

|

2.5 mm²/s

|

2.5 mm²/s

|

3.0 mm²/s

|

4.5 mm²/s

|

4.5 mm²/s

|

5.5 mm²/s

|

6.5 mm²/s

|

9 mm²/s

|

4.32 mm²/s | 4.4 mm²/s | 3.0 mm²/s |

|

Aromatics (UV)

|

HM-14-Labor

|

max. 2000 ppm

|

max. 1000 ppm

|

max. 2000 ppm

|

max. 1000 ppm

|

max. 1000 ppm

|

max. 1000 ppm

|

max. 1000 ppm

|

max. 1000 ppm

|

max. 1000 ppm

|

5.4% v | 4.5% v | 9% v |

|

Pour Point

|

DIN ISO 3016

|

|

max. -40°C

|

max. -10°C

|

max. -30°C

|

max. -20°C

|

max. -10°C

|

max. -5 °C

|

max. 5 °C

|

max.-30 °C

|

max. -6°C | max. -5°C | max. -33°C |

|

FDA CFR 21 178.362

|

B

|

B

|

B

|

B

|

B

|

B

|

B

|

B

|

B

|

B

|

B | B | B |

|

CAS. No.

|

|

64742-47-8

|

64741-91-9

64742-46-7

64742-47-8

|

64742-47-8

|

64741-91-9

64742-46-7

64742-47-8

|

64741-91-9

64742-46-7

|

64741-91-9

64742-46-7

|

64741-91-9

64742-46-7

|

64741-91-9

64742-46-7

|

1174522-19-0 | 64742-80-9 | 64742-80-9 | 64742-80-9 |

|

EC Number

|

|

926-141-6

|

927-632-8

|

927-632-8

|

927-632-8

|

919-029-3

|

919-029-3

|

919-029-3

|

919-029-3

|

919-029-3

|

919-006-8 | 919-006-8 | 920-360-0 |

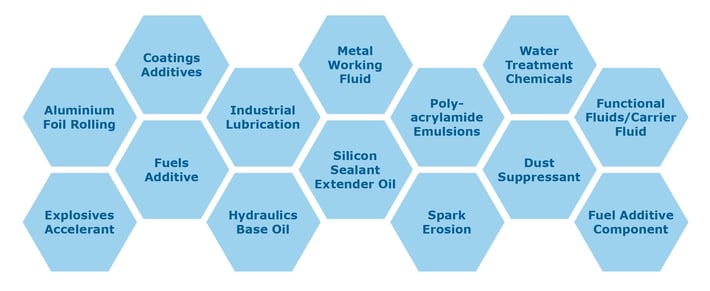

Application

Food and beverage production

High quality requirements are placed on lubricants and process oils used in the food processing industry. NSF certification guarantees food safety. NSF H1-certified products may be used in production if contact with food is technically not completely avoidable. The lubricants must be food-safe, neutral in taste and odour and safe for health.

→ For food processing industry we recommend our NSF H1-certified base oils Pilot® 200R, Pilot® 261R, Pilot® 400H, Pilot® 500H and Pilot® 900

Additives

Fuel Additives & Flow Improver:

Fuel Additives & Flow Improver in fuel prevent and remove deposits, enable lubricity and guarantee cold stability. For this purpose, the various additive components are pre-dissolved in a matrix and then stirred into the product.

→ For fuel additives we recommend Pilot® 140 and Pilot® 900

Lubricant Additives:

Similar to fuels, lubricants are also additivated to achieve certain performance characteristics.

→ For lubricant additives we recommend all of our Pilot® oil grades

Defoamers:

Foam formation occurs in a variety of processes and must be reduced or eliminated. Low-viscosity middle distillates can be used as a good and inexpensive alternative to silicon-based products. Users of such formulated products include mining, breweries, the food industry, refrigeration, wastewater treatment and other wet processing.

→ For defoamers we recommend Pilot® 250H and Pilot® 900

Paints & Coatings:

Additives have also to be added to the formulation in pre-dissolved form for paints, varnishes and coatings.

→ For paints and coatings we recommend Pilot® 150H, Pilot® 400H and Pilot® 500H

Hydraulic oils:

These oils transmit pressure and energy in hydraulic systems. Important for hydraulic fluids are low viscosity, high aging resistance and the widest possible operating temperature range.

→ For hydraulic oils we recommend Pilot® 295SR and Pilot® 900

Textile and leather

In many cases, very light lubricants and antiseizes are required when processing fibers, yarns, and fabrics. Spindle oils are free of resin-forming components and do not discolor textiles or yarns. Low-viscosity oils are also used in leather production, for example for emulsions.

→ For textile and leather we recommend Pilot® 400H and Pilot® 500H

Aluminium rolling oils

For aluminium rolling, our Pilot® oils offer controlled viscosities and a uniform boiling range with excellent purity consistency, while providing high evaporation performance and leaving no residues during the critical post-rolling tempering process. The FDA approvals for these Pilot® oils facilitates further clearance for the use of the foils made from them for food packaging.

→ For aluminium rolling we recommend Pilot® 200R

→ For heavier applications, such as rolling sheet metal and ingots, we recommend Pilot® 250H

Metalworking

The product portfolio of Pilot® oils offers a wide range of different physical and chemical properties. This is how important performance parameters for demanding industrial applications can be easily acheived. Pilot® oils are used in a variety of high performance applications including cutting oils, cutting emulsions, aluminium foil and sheet rolling, steel rolling, extrusion and forming oils, honing and grinding oils, quenching oils, EDM/spark erosion, corrosion inhibitors, hydraulic oils and industrial cleaners.

→ For metalworking we recommend Pilot® 140, Pilot® 250H, Pilot® 275H, Pilot® 400H and Pilot® 500H

→ For spark erosion technology we recommend Pilot® 400H and Pilot® 900

Silicone sealants

Our Pilot® oils are characterized by excellent material compatibility and solvent properties and are therefore used as extender oils in silicone sealants. The extender oils have a low aromatic content, a mild odor and are ideal for acetoxy and alkoxy applications.

The UV stability of our Pilot® extender oils provides excellent anti-aging and stable color properties.

→ For silicone sealants we recommend Pilot® 250H, Pilot® 275H and Pilot® 300H+

Water treatment

Municipal and industrial wastewater must be treated and clarified before it is discharged into the sewer system. Particularly in the industrial sector (mining, paper), there are often suspended solids that do not settle completely even after long periods of rest. Ready-made acrylate oil emulsions facilitate clarification, and often no settling tanks are necessary.

→ For water treatment we recommend Pilot® 250H, Pilot® 275H, Pilot® 300H, Pilot® 300H+ and Pilot® 400H

Construction, building and industry

Pilot® oils offer a wide range of uses in building and construction. Among other uses, they are ideal for use as mould release agent in concrete applications. Some oils are used extensively in both hot and cold bitumen emulsions for road surfacing and jointing compounds. Latex-modified bitumen emulsions require special plasticity, which our aromatic-rich Pilot® oils ensure in the mixing process.

→ For shuttering oils we recommend Pilot® 250H, Pilot® 275H, Pilot® 400H and Pilot® 500H

→ For explosives we recommend Pilot® 140

→ For dust binders we recommend Pilot® 200R and Pilot® 900

→ For bitumen applications we recommend Pilot® 275H, Pilot® 400H, Pilot® 500H and Pilot® 295SR

Plasticiser

Some plastics, such as PVC, are used almost exclusively with plasticisers to achieve the desired properties. For some time now, phthalates have been regarded as critical and alternatives have been called for. Certain middle distillate cuts are suitable alternatives for this purpose.

→ For plasticiser we recommend Pilot® 140 and Pilot® 150H