The printing ink industry, like many industries, is subject to constant change. The trend is moving towards Printing Ink Distillates (PID) with low aromatics content. For special applications, however, the classic products remain the best choice. Test Oils continue to serve as a reference for the highest quality standards. In this article, you can read about the applications in which they have proved particularly successful.

Only specific Middle Distillates are used in Printing Ink Distillates

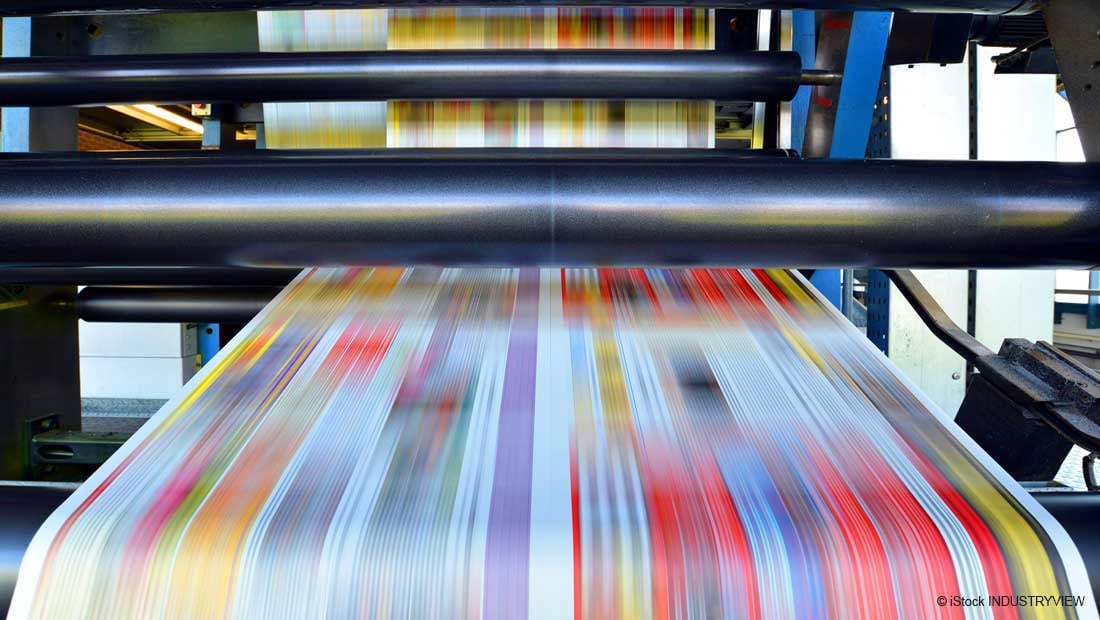

Offset printing is the most widely used printing process. In this process, the ink is transferred to the substrate in a matter of seconds via various rollers. The ink has a consistency of very soft butter and consists of additives, pigments, resins and, above all, the Printing Ink Distillate (PID).

Production process & technical overview

The Middle Distillates are basically from the same family as diesel fuel, but have special properties because they are designed to be solvents. Ideally, they are not produced by blending different cuts, but entirely by distilling of selected raw materials. This is the only way to obtain a uniform and predictable drying properties of the paint.

Important topics for customers are:

- the boiling range

- the solubility of the Printing Ink Distillate and

- different molecular compositions depending on the resin and the pigment.

Paraffins and isoparaffins have a rather low solubility - naphthenes and aromatics have a better one. For this reason, the solubility is characterised by the aniline point, and serves as a good indicator of the overall solubility of the system.

Trend towards more sustainability

In general, the trend is moving towards aromatics-free Printing Ink Distillates (PID) and high aniline points. They have a lower impact on the environment and the people. Nevertheless, there are always niche applications for specific Printing Ink Distillates (PID) that still contain some aromatics or those that consist of only one type of molecule.

Solutions from a single source: Printing Ink Distillates from Haltermann Carless

Haltermann Carless offers solutions for the entire offset range; all or our products are distilled and not blended:

- Pure paraffins for sensitive applications such as banknote printing or revenue stamps.

- Low-aromatic and aromatic-free solvents for offset, sheetfed and heatset printing (Paraset® and PKWF®).

- Special Printing Ink Distillates (PID) for coldset printing (PKWF® and Printosol®).

|

Excursus: The new hydrogenation plant, which will be commissioned at the German production site in Speyer at the end of 2021, will enable Haltermann Carless to even better meet the increased demand for aromatics-free Printing Ink Distillates (PIDs). |

Conclusion

Printing Ink Distillates (PID) are an essential component of printing inks for offset printing. They are produced from Middle Distillates and are characterised by defined boiling ranges, specified solubility and high quality consistency. Haltermann Carless offers the entire range of Printing Ink Distillates (PID) and is well prepared for the future - thanks to the new hydrogenation plant at the Speyer site.