Pentane blowing agents are widely used in the insulation industry. Since the performance and properties of Polyurethane (PU) and Polyisocyanurate (PIR) foams can vary considerably - depending on the isomer used - Haltermann Carless has conducted a study to take a closer look at the behaviour of blends consisting of the three isomers n-Pentane, iso-Pentane and Cyclopentane. The results of these tenary blends look promising and might offer additional benefits to the insulation industry.

Pentane blowing agents are widely used in the insulation industry. Since the performance and properties of Polyurethane (PU) and Polyisocyanurate (PIR) foams can vary considerably - depending on the isomer used - Haltermann Carless has conducted a study to take a closer look at the behaviour of blends consisting of the three isomers n-Pentane, iso-Pentane and Cyclopentane. The results of these tenary blends look promising and might offer additional benefits to the insulation industry.

In the recent past chlorinated and fluorinated blowing agents were commonly used. More recently and against a backdrop of environmental pollution and global warming concerns, Pentanes now account for more than 50% of all blowing agents used in the Polyurethane (PU) and Polyisocyanurate (PIR) industry. Whereas pure Pentanes and their binary Pentane blends are widely used, blends of all three isomers are rare and not described in scientific literature. This notwithstanding, ternary blends may have advantages for insulation board manufacturing that have so far not been identified.

As the only European company that is in a position to manufacture all three Pentane isomers - n-Pentane, iso-Pentane and Cyclopentane – Haltermann Carless has a great interest to evaluate the potential benefits of tenary Pentane blends and has therefore conducted a study on this.

High-performance insulation thanks to Pentane

Insulation materials require a blowing agent to achieve the desired foaming for insulation performance. However, depending on the isomer used, the performance and properties of the foams can vary significantly. High-performance Pentanes and Pentane blends are therefore of great interest to manufacturers of PU and PIR foams. Thus, what advantages could blends of all three isomers - n-Pentane, iso-Pentane and Cyclopentane - offer? Haltermann Carless has been researching just that.

Pentanes for the insulation industry: Experimental setup of the tenary Pentane blends study

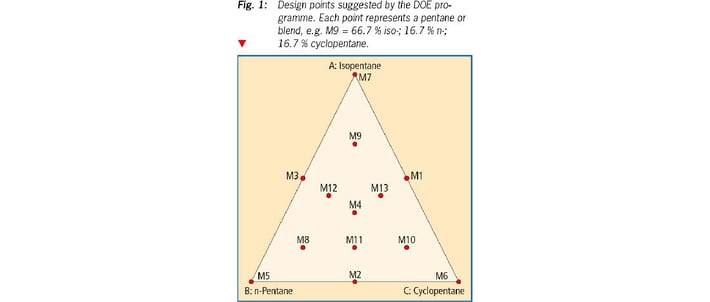

To better understand the behaviour of tenary Pentane blends, a series of experiments were set-up to further investigate this. For our experiment a standard PIR formulation was used to compare the performance of the different Pentanes and blends. These experiments were planned and evaluated with the help of a design-of-experiment (DOE) software. Haltermann Carless used the services of a specialised external laboratory to conduct the experiments. The behaviour of the PIR and the Pentanes during the foaming process was recorded. In further steps, the fresh foam was examined for its insulation properties, artificially aged, and re-examined. The programme suggested ten blends and the three pure pentanes for foaming (fig. 1, tab. 1).

Source: Haltermann Carless

Attention was paid to the following:

- The polyols, isocyanates, catalysts and additives used correspond to the common industry standard.

- With an index of 2.5, the PIR foam is comparable to the foams used for sandwich panels.

- The foams have passed the fire resistance test according to DIN 4102.

- The foam rating was monitored during the tests.

- The dimensional stability, thermal conductivity and thermal conductivity after ageing were then measured.

- For thermal conductivity, two sets of data were measured at 15°C and 25°C.

Results

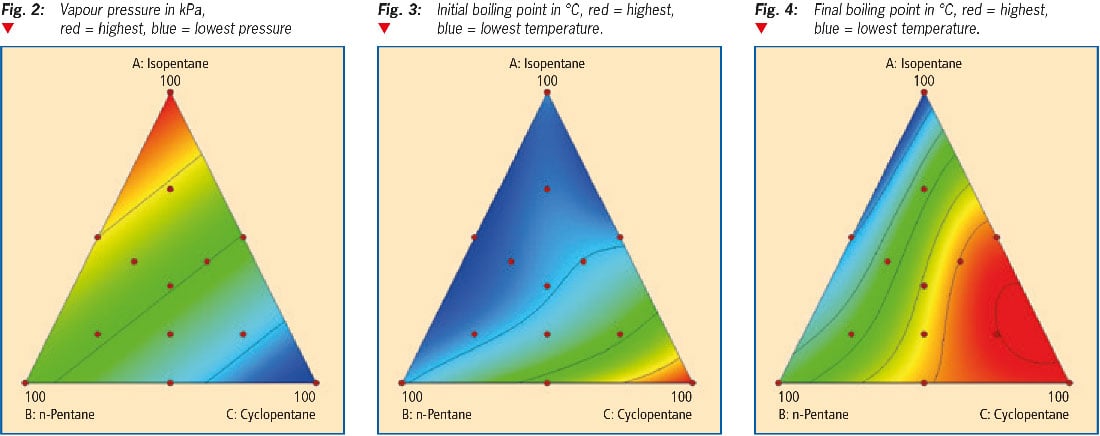

After creating then blends, all samples were analysed for vapour pressure, initial and final boiling point. The results of each experiment were fed into the DOE programme, presenting the analysis of the data as a heat map (fig. 2). Initial and final boiling point showed quite linear behaviour. The blends followed very much the trend set by the pure Pentanes (fig. 3 and 4).

Source: Haltermann Carless

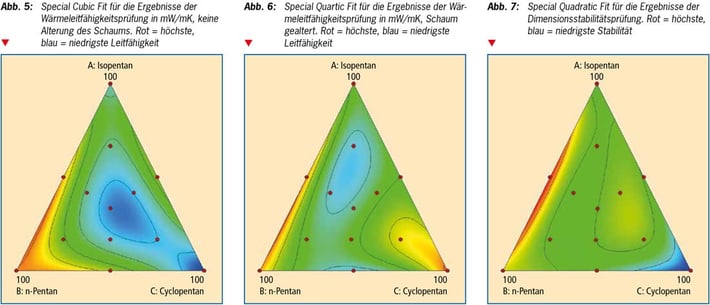

Conductivity of heat was measured parallel to the upstream of the foam (fig. 5). Two sets of data were measured at 15 °C and 25 °C. The density is very similar in all cases and it can be assumed that the difference has little impact on the heat conductivity. The best result was obtained with pure Cyclopentane. After ageing the foam for 48 h at 70 °C, the result was different (fig. 6).

The fit of the data was quite good in the case of dimensional stability (fig. 7). Surprisingly, the blend of all three Pentanes in equal parts has an acceptable stability, although performing less optimally in the case of heat conductivity. iso-Pentane/n-Pentane blends have the best stability over time.

Source: Haltermann Carless

Read also:

- Haltermann Carless Pentane: Tailor-made and ecologically beneficial

- Haltermann Carless: Largest Cyclopentane capacity for the world market

Conclusion: Pentanes for the insulation industry offer numerous advantages

The three pure Pentanes showed a performance as expected. Literature, experimental results and model are consistant with the findings. The Pentanes blends showed mostly the expected behaviour but also revealed some interesting details.

- Cyclopentane blown foam has excellent insulation behaviour but deterioates as expected over time.

- Blends of iso-Pentane are fairly stable and have a insulation performance that can come close to foams made with Cyclopentane over time.

- The ternary Pentane blends show a good overall performance. Dimensional stability and heat conductivity is always good or very good, also after ageing the foam.

Our experimental approach includes comparable basic set up of a few experiments, but the interpretation shows potential for ternary Pentane blends to be investigated as blowing agent for more applications. Ternary Pentane blends show potential for excellent long-term performance, an important fact in building construction.

»Would you like to learn more about our comprehensive Pentane portfolio? We are happy to advise you!