/Haltermann-Carless-Deutschland_Hamburg_2500x500px_211028.jpg?width=300&name=Haltermann-Carless-Deutschland_Hamburg_2500x500px_211028.jpg)

Production Site Hamburg

Speyer – ein Standort mit Zukunft

Speyer ist ein strategischer Produktionsstandort für Haltermann Carless. Kontinuierliche Weiterentwicklungen und Investitionen sind wichtiger Teil der über 50jährigen Geschichte. Mit rund 120 Mitarbeiter produzieren wir ein umfangreiches Portfolio mit hohen Ansprüchen an Qualität und Nachhaltigkeit. Dafür investieren wir in moderne Technologien, verbesserte Produkte und nachhaltige Lösungen.

Speyer – ein Standort mit Zukunft

Speyer ist ein strategischer Produktionsstandort für Haltermann Carless. Kontinuierliche Weiterentwicklungen und Investitionen sind wichtiger Teil der über 50jährigen Geschichte. Mit rund 120 Mitarbeiter produzieren wir ein umfangreiches Portfolio mit hohen Ansprüchen an Qualität und Nachhaltigkeit. Dafür investieren wir in moderne Technologien, verbesserte Produkte und nachhaltige Lösungen.

Haltermann Carless in Hamburg – a site with a long tradition of fuel expertise.

Hamburg is a Haltermann Carless site rich in tradition with particular expertise for our global customers in the automotive industry. At this site we produce Reference Fuels, Test Fuels and Certification Fuels, which are used in the research and development of engines as well as for comparable industrial applications, e.g. in the construction of power tools.

With our ISO/IEC 17025 accredited laboratory, we ensure our high quality standards and are strong partners to industry in the development of complex solutions for modern Fuels, high-purity Hydrocarbons, Pentanes and Middle Distillates.

Facts at a glance:

-

Storage and blending facilities for liquid mineral oil products

-

2 semi-automatic filling lines for industrial packaging

-

6 filling stations for road tankers and rail tank cars

-

1 jetty for seagoing and inland vessels

-

steam generation plant-operated with low-sulfur fuel oil

-

10 kV transformers and 400 V switchgear to supply electrical power

-

110 tanks (dedicated)

-

140 feed pumps

- 130,000 m² industrial area with access to the Port of Hamburg

Control storage for 50,000 m3 of liquid mineral oil products (tank volumes from 10 m3 to 2,500 m3)

- Seaport Hamburg shipping pier

- Rail connection to the Hamburg port railway and DB Cargo

- Modern road connections to the port terminals and motorways for bulk and general cargo transport

- Sea and inland waterway vessels

- Tank wagons

- Tank trucks

- Iso-containers

- IBC containers

- 200-liter drums

- Cans

- ISO 9001 (Quality)

- ISO 14001 (Environment)

- ISO 50001 (Energy)

- ISO/IEC 17025 (Laboratory)

- Test and Reference Fuels

- High-purity Hydrocarbons

- Solvents

- Pentanes

- Middle Distillates

- Synthetic components for Test Fuels

- Polar raw materials from renewable sources

Portfolio

Products made in Hamburg

At our production site in Hamburg, we provide our customers with a range of modern, high-quality and certified products and thus support them on their path to climate neutrality.

Test and Reference Fuels

Sustainable mobility goes far beyond the more efficient use of means of transport. It includes important climate protection criteria. Thus, sustainable mobility means a reduction of emissions, but also a lower consumption of resources.

The development and testing of modern engines requires standardised Test and Reference fuels. They help to comply with emission limits in the further development of materials and lubricants in the automotive industry, but also in the construction of power tools for gardening and forestry.

Fuels made from renewable sources

Our contribution to sustainable mobility is clear: Our goal is to enable a 95 % reduction in greenhouse gas emissions (GHG) with our Performance Fuels. Our synthetic components for Test Fuels and our feedstock from renewable sources make the difference and support our customers in achieving their sustainable climate goals.

Additional products

- High-purity Hydrocarbons

- Performance Solvents

- Pentanes

- Middle Distillates

Unsere Expertise für die Automobilindustrie

Unsere Expertise für die Automobilindustrie zeigt sich auch in unseren Anlagen. Dazu gehören beispielsweise unsere hochpräzisen Mischstationen mit einer Produktionskapazität von 600 bis 650 Mischungen pro Jahr. Hinzu kommen die Abfüllung und Verpackung von ca. 35.000 Industriefässern pro Jahr.

Ecovadis

Unsere umfangreichen Bemühungen wurden mit dem Gold-Status von Ecovadis gewürdigt.

Expertise for the automotive industry

Our expertise for the automotive industry is also evident in our equipment, such as our high-precision mixing stations with a production capacity of 600 to 650 blends per year.

In addition, there is the filling and packaging of approx. 35,000 industrial barrels per year.

Accredited laboratory

Centrepiece for quality and development

Our laboratories, directly on site, offer you multiple services. Because in addition to quality testing, we research and develop sustainable products, new developments or customised formulations. We are proud to be accredited according to ISO/IEC 17025.

Laboratory for quality assurance

For our customers in the automotive and engine industry, certified products are the be-all and end-all. Quality testing therefore requires

- extensive testing and analysis facilities

- modern laboratory equipment

- individual quality parameters and

- highly qualified employees

Laboratory accredited to ISO/IEC 17025

With our comprehensive on-site lab service, we have obtained the important accreditation acc. to ISO/IEC 17025. We carry out particularly fast and comprehensive quality testing and provide you with consistently high quality standards and the quality certificates that are crucial for the automotive industry.

Lab tests:

- Density measurement

- Flash and aniline point

- Cold flow behavior (e.g. pour point, CFPP)

- Distillation profiles

- Vapor pressure

- Tests for oxygenated molecules such as ketones

- Individual quality parameters possible

Laboratory for Research & Development

In addition to quality assurance, our laboratories conduct research and development programms on future products or customised formulations together with customers.

As a member of the CEC Reference Fuel Development Committee, we understand the needs, trends and regulations of the engine industry.

Exkurs:

Was macht der CEC?

CEC steht für Comité Européen de Coordination (European Committee for Coordination) und für die Entwicklung von Performance Tests in den Bereichen Kraftstoffen, Schmiermitteln und weiteren transportbezogenen Flüssigkeiten.

Die Mitglieder des CEC sind Unternehmensvertreter aus den Bereichen Schmierstoffe, Kraftstoffe, Additive, Automobilhersteller, Gerätehersteller, unabhängigen Laboratorien und Hersteller von Kfz-Flüssigkeiten. Und in Zusammenarbeit mit:

- ACEA: European Automobile Manufacturers’ Association

- ATIEL: Technical Association of the European Lubricant Industry

- ATC: Technical Association of Petroleum Additive Manufacturers

- CONCAWE: European body for the conservation of air and water

Supply Chain

The Hamburg site has a direct connection to the Port of Hamburg - the gateway to the world. We are in the position to offer our customers the broad range of supply chain infrastructure:

- Strategic location with direct connection to the Port of Hamburg

- Own water jetty with a draught of approx. 9 m, suitable for barges and seagoing vessels up to 20,000 t for highly flammable resp. 30,000 t for flammable substances

- 6 loading areas for road and rail

- Calibrated track scales

- Calibrated platform scale for road tankers

Individual packaging units

Our packaging units are as diverse and individual as our transport options. We supply our customers by sea and inland waterways, tank wagons and tank trucks. We also offer our products in iso-containers, IBC-containers, 200-liter drums or cans.

Mehr erfahren

Fast, safe and reliable delivery

We can offer you tailor-made transport and packaging solutions while working closely with our logistics partners for a fast, safe and reliable delivery.

Mehr erfahren

Wussten Sie es schon? Unser Standort in Hamburg ist die Wiege eines unserer Gründerväter!

1898: Johann Haltermann gründete in Hamburg-Wilhelmsburg ein Unternehmen, das Rohteer aus den Hamburger Gaswerken veredelte.

1920er: Haltermann entwickelte einen benzolbasierten Kraftstoff für Ottomotoren, der unter dem Markennamen "Ergin" vertrieben wurde.

1950er: Mottenkugeln aus Naphthalin wurden hergestellt.

1960er: Hochreine, zertifizierte Bezugskraftstoffe (n-Heptan+ i-Oktan) konnten mit einer neuen Destillationsanlage nun hergestellt werden.

1970: Eine Destillations-Pilotanlage wurde in Betrieb genommen, um Pilotversuche für kundenspezifische Destillationsprozesse zu ermöglichen.

1990er: Die Anlage wurde schließlich in eine Misch- und Lageranlage für die Herstellung und Lieferung von speziellen Kohlenwasserstoffflüssigkeiten, petrochemischen Lösungsmitteln sowie Test- und Referenzkraftstoffen umgewandelt.

Erfahren Sie mehr über unsere traditionsreiche Geschichte!

Did you know….

that our site in Hamburg is the cradle of one of our founding fathers?

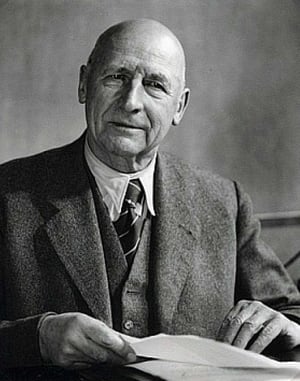

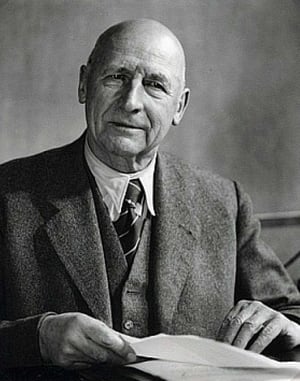

![Haltermann-Geschäftsleitung-003_1100x1400px_211021]()

1898

Johann Haltermann founded a company in Hamburg-Wilhelmsburg, Germany, that refined raw tar from the Hamburg gas works.

![Haltermann-Transportation_2]()

1920s

Haltermann developed a benzene-based fuel for gasoline engines, which was marketed under the brand name "Ergin".

![AdobeStock_©-Bowonpat_443805336_Mottenkugeln_1100px]()

1950s

Production of mothballs made from naphthalene.

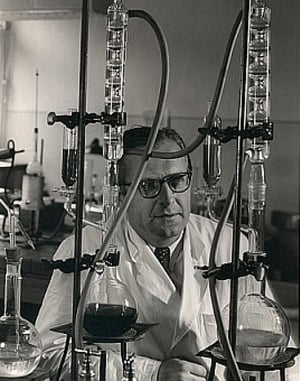

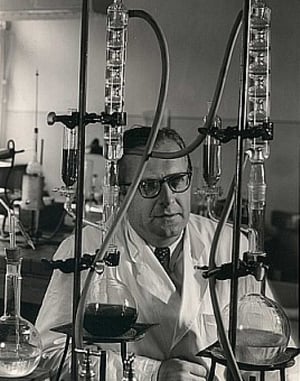

![HaltermannTechnikum004_1100x1400px_211021]()

1960s

High-purity, certified reference fuels (n-heptane + i-octane) were produced with a new distillation unit.![HaltermannTechnikum008_1100x620px_211021-1]()

1970s

A distillation pilot plant was commissioned to allow pilot testing of custom distillation processes.

![Pic_HC_HH_production site_6]()

1990s

The plant was eventually converted into a blending and storage facility for the production and supply of specialty hydrocarbon liquids, petrochemical solvents, and test and reference fuels.